Table of Contents

- Types of Metal

- 10 Different Ways of Cutting Metal

- 1. Use Abrasive Blades

- 2. Angle grinder with ferrous metal cutting diamond blades

- 3. Circular Saw – A Good Device to Cut Metal

- 4. Use Miter Saw to Cut Aluminum

- 5. Grinding Disk

- 6. A Smart Way to Cut Metal With Reciprocating Saw

- 7. Use Oscillating Tool

- 8. With The Help Of Band Saws

- 9. Use Thermal Cutting Technology

- 10. Use Power Hacksaw

- Safety Tips for Cutting Metal

- Final Verdict

There are several ways on how to cut metal fast, hence giving you options to choose the one that is easier to access. This guide is meant to provide you with the most effective power-tool tips for cutting different types of metal and varying thicknesses.

Hacksaws may break before the work is done or take too long to complete the task, but with the right tool for the job, the process will be fast, easy, and safe. One of the most amazing things about hand tools is that you can use them creatively to make them do things that they are not designed to do.

With the right blade or disc, you can cut nearly any type of metal. Whether you are a DIY agent or a professional, cutting metal should not be a problem, so long as you have the right tools and the correct grinding disc or blade. Some people may ask how that can be possible.

The trick lies in matching the blade to the material. If you can do that diligently, then you can cut almost any metal with the familiar power tools like an oscillating tool, reciprocating saw, angle grinder, and circular saw, among many more.

Types of Metal

There are two types of metal. The first type is a ferrous metal, which constitutes all metals that contain iron. To cut this type of metal, you need ferrous-metal-cutting discs or blades. Some of the most common examples of ferrous metal used in construction include steel roofing, steel angle iron, rebar, and steel bolts.

These products are usually labeled for cutting either ferrous or non-ferrous metal to help you identify the right cutting disc or blade. Aluminum and copper are the two most common non-ferrous metals. These are also some of the most commonly cut metals by DIY agents. What is unique about non-ferrous metals is that they are softer and more comfortable to cut compared to ferrous metals.

10 Different Ways of Cutting Metal

There are different ways that DIYers and professionals can use to cut metal. But which is the fastest, easiest and safest? To get the right answer, you need to ask yourself several questions like the following:

- How fast do you want to cut the metal?

- How much space do you have?

- How about the accuracy?

- What sizes of pieces do you want?

- How much budget do you have?

After answering the above questions, then it will be easy for you to pick the right method to use when cutting metal. Here are some methods that you can consider using:

1. Use Abrasive Blades

You can use these blades with various machines ranging from chop saws to angle grinders with many more in between and beyond. You can use it on a circular saw or a die-grinder.

Abrasive blades come in small and large disks, and each power tool that uses the blades requires only a particular size. Therefore, you need to be keen on choosing the right abrasive blade size for the specific device in which you plan to fit.

When you use it with a chop saw, it forms a combination that can cut through steel with straight, square, and most angle cuts.

However, if you are looking for a smaller and more maneuverable tool with an abrasive saw, the circular saw is what you need. You can use it to cut metal sheets and materials that are too large for a chop saw.

One of the die grinder’s most notable strengths is in portability. It may not be suited for large cutting tasks, but you will surely like its performance in notching, cutting small areas, and hard-to-reach parts.

2. Angle grinder with ferrous metal cutting diamond blades

You can use an abrasive metal cutting disc fitted on an angle grinder to cut almost any metal. With this combination, you can cut bolts, sheet metal, and angle iron. However, this method has downsides, the most common ones include the disc wearing down fast.

Others include the diameter shrinking while you use them, and being slower than many other cutting methods. Therefore, we recommend that you use ferrous-metal-cutting diamond blades instead of abrasive discs. The diamond blades cut metal faster and cleaner, last longer, and wear down slower. With these qualities, it is evident that they are far better than abrasive discs.

You can cut metal lath with an angle grinder too. With a ferrous-metal-cutting diamond blade mounted on an angle grinder, this power tool works like a saw to cut the metal mesh. The process will be so swift, and you will be done in no time. You can use a regular masonry diamond blade as the last option where you do not have a ferrous-metal-cutting diamond blade. I have seen some tradespeople use them with excellent results.

3. Circular Saw – A Good Device to Cut Metal

A circular saw is an excellent metal cutting tool, but only if you fit it with the right blade. Though not the best tool for cutting metal, you can improvise and get the best out of it. You can use it with a ferrous-metal-cutting blade to cut through rebar and mild steel up to about 0.375 inches thick.

Remember to put on the right safety gear when using this method and watch out for hot metal chips that the cutting emits. Likewise, keep people away from the scene where all the action is taking place since it is risky for bystanders.

When choosing the right blade, consider choosing the one with innovative features such as non-stick coating, heat build-up resistance, and blade protection against corrosion and gumming. There are various types of blades that you can use here; steel-tooth blades and carbide-tooth blades.

The former is less expensive while the latter is more expensive but lasts longer. Ceramic and metal blend blades provide high heat tolerance and are super hard. Therefore, they do not wear comfortably but provide extra-long cutting life instead. The high heat tolerance is a safety feature as well as a source of quality.

4. Use Miter Saw to Cut Aluminum

Do you want to cut aluminum more effectively and efficiently? Well, a miter saw would be a great power tool for it. All you need to fit it with is a blade designed to cut non-ferrous metals, and you will be good to go. It is a combination that can make accurate cuts on aluminum tubes, rods, and angles with so much ease.

One way to keep safe while using this method is by taping a piece of cloth over and above the motor housing on the saw if it is open and susceptible to collecting metal chips. The cloth will protect both the motor windings and bearings when cutting goes on.

However, it is safe to remove the cloth once the saw goes back to its regular service to prevent the motor from overheating. Wood baker helps trap the aluminum to reduce the danger of metal shards flying everywhere.

Youtube video Credit Tool Review Zone

5. Grinding Disk

Grinding Disk

Rotary tool

You can cut stainless steel accurately and precisely with a grinding disk. Stainless steel comes in many types, but the hardy varieties can be challenging to cut. The simpler stainless steel backlash tiles just need an abrasive metal-cutting disc fitted in a rotary tool to cut.

However, the more robust stainless steel cutting tasks can only be cut better with an angle grinder equipped with an abrasive disc.

A rotary tool is versatile and can cut through a variety of materials, including metal. For metal, you have to fit in the right metal cutting wheels.

Some of its most notable strengths include cutting the metal into smaller pieces and cutting in tight spaces. Therefore, if you need a cutting tool that is more flexible, finding this will be a relief to you.

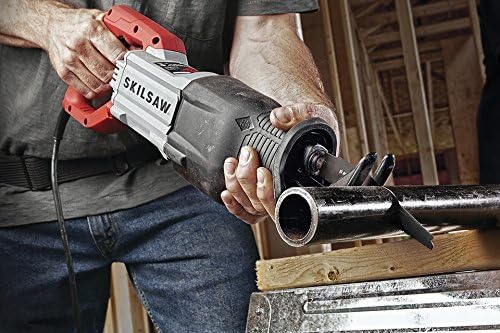

6. A Smart Way to Cut Metal With Reciprocating Saw

You can pair a reciprocating tool with a metal cutting blade to cut all sorts of metal. You can use it in the place of a rotary tool or circular saw. With a sturdy blade, a reciprocating saw can cut thick and extreme metals and cut smaller metals.

It also cuts through metal faster than many power tools that are used to cut the materials. It is essential to be accurate in your blade selection to achieve the best cutting effectiveness with this tool. If you choose the right blade for the metal type you want to cut, chances are you will maximize the saw’s output.

So, whatever a hacksaw can do, a reciprocating saw can do better. With a metal-cutting blade mounted on a reciprocating saw, what you get from that combination is the ultimate power hacksaw. You can use it to cut bolts, pipes, angle iron, and rods.

Similarly, this tool maximizes your chances for safety, and you should regard the safety requirements. Identify the safety features in the device and follow the safety instructions provided by the manufacturer.

To get the best cutting result from your reciprocating saw, you should set it to straight rather than oscillating if you have options to choose. Also, keep the saw speed low if you for longer blade life. It would be an excellent idea to use carbide-tooth or bi-metal blades for high-quality cutting and longer blade life.

7. Use Oscillating Tool

An oscillating tool is suited for cutting metal, especially those that are lodged into the wood. In other words, since it is mostly used to cut wood, it will also cut the metal that is in wood, including nuts, nails, screws, and other metals.

When you buy this tool, it comes with a metal-cutting blade. So if you need a tool that can cut all sorts of metal within the wood as you cut the wood itself, you should bank on an oscillating tool. It does the cutting efficiency and is one of the fastest you can get under this category.

Also, the oscillating tool is known to cut in tight spaces. It easily accesses metal in squeezed areas and cuts them without touching parts that it should not. It is also suitable for making flush cuts. You just need to fit in the right metal cutting blade for each function, and the process will be a success.

If you want to cut corroded mounting nuts on faucets and toilets, an oscillating tool can do it well. Likewise, you can use it to cut automotive bolts, plumbing pipes, and nails hidden where extensive metal-cutting tools cannot fit.

8. With The Help Of Band Saws

This machine is also used for cutting metal, which is just one of the many materials that you can use to cut. It cuts right, and its blades tend to last longer than those used by most other tools. You just need to be more careful to match the speed and tooth pitch with the material.

It also requires you to use flood cooling to improve cutting and blade life. Band saws have moderate cutting speed and are reasonably accurate. The level of accuracy is somehow influenced by how well you set it up and use it.

9. Use Thermal Cutting Technology

You can use thermal cutting methods to cut metal fast. There are various thermal cutting processes, including flame cutting, plasma cutting, and laser cutting. Thermal cutting uses an energy source to produce heat that it uses to cut metal.

It heats a specific part of the metal to liquefy it until the metal is divided. The molten metal is blown away to create a cut. Thermal cutting is way faster than most other metal-cutting methods.

10. Use Power Hacksaw

A power hacksaw can be a great method of cutting large sizes of tough metals like steel and the like. If you are cutting metals with a diameter of more than 15mm, it can be tough to use a manual hacksaw. Therefore, you need a power hacksaw to make cutting fast and effortless. The tool features a heavy duty that moves forwards and backward while cutting.

It has a convenient vice that holds the metal you are cutting in place. You only need to turn the handle to loosen or tighten it. When you are cutting metal, the blade heats up fast, therefore, you need to use coolant on the blade. If you don’t use a coolant, the blade can overheat and eventually break.

It is important to get a power hacksaw that has a quality steel blade. If you need an affordable option, you can get power hacksaws with a carbon steel blade. Also, the more the number of teeth, the smoother your cuts will be.

Safety Tips for Cutting Metal

The safety of the user and bystanders is essential when cutting or grinding metal since the processes often send tiny shads and chips of metal flying everywhere. These small particles are usually hot and sharp. That is why you need to protect yourself against them so that they do not burn, cut, or injure your eyes or any other part of the body. There are several safety precautions that you should always take when using these tools. This section presents to you the essential safety tips.

Read Safety Precautions

The metal cutting discs and blades usually have safety precautions printed on them. Reading these precautions and instructions should be the first thing to do before you begin working. Then observe them just the way you have to understand what is required of you.

Personal Protective equipment

Also, wear safety glasses to protect your eye. In cases where glasses may be too small, you need a face shield since it protects the entire face. Besides protecting your face, you should also need to protect your ears. That is why you need hearing protection.

Ensure that you cover every exposed skin with a long sleeve shirt, gloves, and pants to protect your skin. Similarly, do not touch freshly cut metal until it cools down. You may get serious burns from freshly cut metal because they heat up excessively when you cut or grind them.

The gloves also help you avoid getting burned by these metals just in case you forget and try to touch them before they cool down. After cutting metal, some of them may develop sharps areas around the cut places that you should be aware of. When touching such sharp regions, you need to wear gloves to protect yourself from the cuts that they may cause you.

Proper Clamp

Before you begin to cut any metal with whatever tool you choose, you must first securely clamp the metal. Make sure it is tightly held in place so that no amount of force from the cutting machine can throw it off the clamping tool. It would be too risky to begin cutting a loosely held iron with a power tool. It can lead to serious injuries or even fatality in some cases.

Keep People Away

Similarly, before you start to cut anything using a power tool, make sure you do not allow anyone near you. If anyone has to stay closer, make sure they are wearing all the necessary safety gear, including face and ear protection.

Final Verdict

I hope you now know some tips to cut metal fast. Before you begin to cut metal using any of these methods, one of the most important things you need to do is wear appropriate safety gear. Also, choose the right grinding disc or cutting blade for the materials. These are two of the most fundamental tips for cutting metal fast and safely. With all these many available methods, you should choose the one that will give quality or the most desired results. Use this guide to understand the best methods to use whenever you need to cut metal fast.